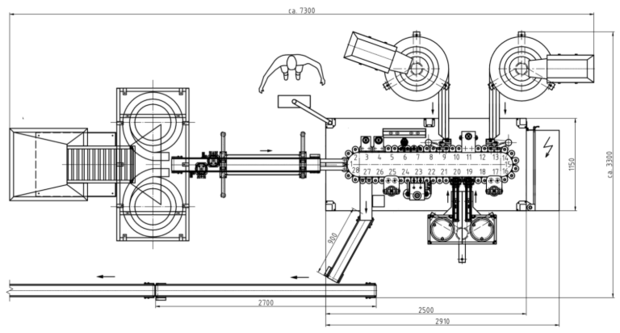

Solving highly complex packaging problems with our platform AL110

Our AL110 platform is particularly suitable for highly complex packaging problems. The basis of the platform is the oval design in different sizes – small, medium and large. This design allows you to adapt the platform to your requirements and thus obtain exactly the machine you need. Why use two or three machines for your products when our AL110 platform can do all the work?

The AL110 platform at a glance

The AL110 offers the latest technology and a unique modular design. As a result, many tasks can be realized in a small space. The compact design is especially valuable if you do not have much space available. The workstations are arranged around the clocked, oval transport system within the housing. Where your competitors need two or three machines to perform their packaging tasks, you only need one machine as a platform for many functions. The AL110 platform is therefore an upmarket filling, capping and assembly machine with an oval design for exceptional versatility. Different packages and products can be processed by our platform AL110 without any problems. For the station drives we use our servo technology. This enables a much less time-consuming format change and maintenance. You can make better use of the time saved!

Facts of the AL110 platform

Our platform AL110 can process up to 100 bottles per minute. It can also integrate caps, spray dispensers, crimp and put-on caps. Of course, the AL110 platform is GMP compliant and suitable for pharmaceutical production. Our platform AL110 is also the ideal workstation for round and unstable containers. Its flexibility and versatility make it a reliable all-rounder. So if you are looking for a particularly sophisticated machine that offers you a solution to your packaging problems, please contact us and we will be happy to advise you!

Watch AL110 on YouTube here!