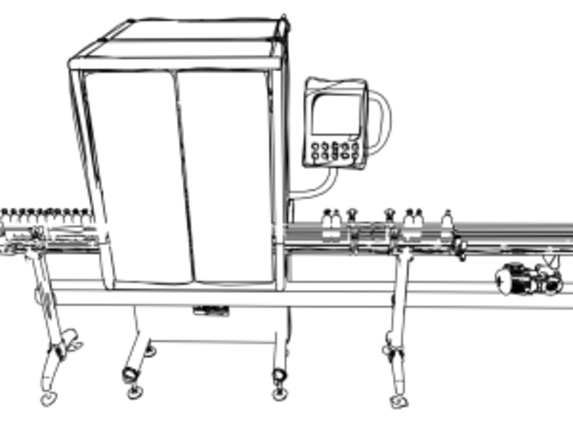

AL101 – In-Line-Filler

In the field of can and bottle filling, we offer our customers the AL101 in-line filler. Our in-line filler AL101 can be designed with up to 8 digits. The plant can be moved at any time and thus be placed at existing conveyor belts. Due to the modular construction, different filling principles can be used. This makes it possible to fill the whole range of liquid to highly viscous products without any problems. The flexibility of the AL101 in-line filler allows it to be used in all industries. The machine is suitable for the food and chemical industries as well as for the cosmetics and pharmaceutical industries.

The lowering movement into the containers is servo-controlled. Under-mirror or above-mirror fillings are flexibly programmed and stored so that you can access them at any time. All parts that come into contact with your products are made of AISI 316L stainless steel. Depending on the requirements, the containers can be fed to the conveyor belt manually or automatically. We will also find the optimum solution for your filling processes. Just contact us.

Mobile filling plant, versatile

The AL101 in-line filler is versatile and offers a particularly high degree of flexibility due to its mobility. Benefit from a row filler that can be optimally adapted to your needs. Please contact us and we will be happy to support you in your projects!

Please contact us and we will gladly support you in your projects!