Filling machines for the cosmetics industry

In the cosmetics industry, the challenge for machine manufacturers is to design their filling systems for cosmetic products as flexibly as possible. Especially in this industry, the variety of containers is extremely diverse, as packaging accounts for a large part of marketing. At the same time, the cosmetics industry fills a great variety of products with very different properties: these range from liquid, flammable products such as perfume to highly viscous products interspersed with glitter. The containers are as diverse as their products: Tubes in all seal shapes, jars, bottles in all conceivable shapes and with the most diverse closures, mascara sticks, nail polish bottles, spray cans and much more.

The trend is towards small series, but ever larger numbers of batches. Gustav Obermeyer is therefore faced with the challenge that, on the one hand, a large number of products must be processed on the same line, but on the other hand, the time required for format changeover must be kept as short as possible.

Gustav Obermeyer took up this challenge and launched a variety of systems on the market precisely for this purpose. And as a special machine manufacturer with a flat hierarchy and manageable communication channels, we can fulfil (almost) every wish of the marketing department of cosmetics manufacturers, no matter how unusual it may be.

Filling tubes with our filling machines

Of course, our tube fillers are ideally suited for these tasks. The rotary transfer machines are extremely compact, the format sets are cost-effective and the changeover times to another format are as short as possible. On some of our tube fillers far more than a dozen formats are produced! If higher outputs are required, Gustav Obermeyer offers an oval filler which can be equipped with several stations and can process up to 220 tubes p.m. And, of course, various types of tube feeding and further processing can also be ordered from Gustav Obermeyer. And in order to meet the challenge of very many small batches with small series sizes, we offer our most compact fully mechanical tube filler in the world: the TU25, which can be converted from one format to another in just a few minutes.

Cosmetics require high quality, which our filling lines offer

What actually is quality? Naturally, the machines are manufactured to a high standard, GMP-compliant and durable, and are robust and almost every part is made of stainless steel. The design of our machines – meanwhile also a requirement for the modern factory – is very attractive, the electronics offer good connection to the BDE of the company. The parameters of 100 formats and more can be stored on our machines. But a very special sign of quality is our service. This is of great importance in the cosmetics industry because of the use of a variety of formats and the high demand for advice even after installation of the machines, when new formats are added.

Machines for the cosmetics industry by Gustav Obermeyer

The machine types that Gustav Obermeyer can offer for the cosmetics industry are as diverse as the products and their containers. Of course, the various types of tube fillers as rotary transfer machines are available – the semi-automatic TU25, the larger, fully automatic TU60 and TU80 and the TU110, which is designed as an oval filler.

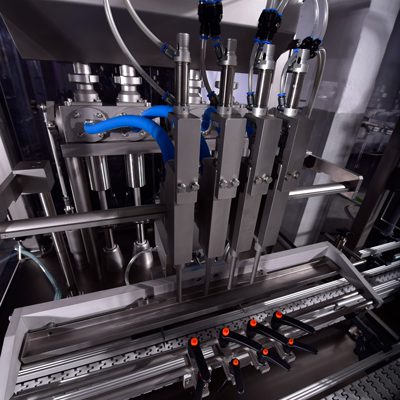

All tube fillers can, of course, process metal, PE and laminate tubes in a wide variety of seal shapes, and PP tubes if required.

We have developed different platforms for the various other container types. The rotary transfer machines are based on the AL31 (for vials, jars, but also mascara and nail varnish) and offer all possible types of stations for closing the containers. In addition, the Gustav Obermeyer offers in-line fillers based on the AL101 which can be equipped with rotary piston, flow meter AND with reciprocating piston in different numbers of filling stations. In addition, the GSM500 automatic closing machine is available. All machines can also be produced in EX-protection.