Jars and doses continue to be a preferred form of applications in the cosmetic, pharmaceutical and food industries. This is due to the wide range of possible uses, whether for ointments or creams or as pastes in the food industry. But cans are also a preferred form for many areas of application in the chemical industry.

Our jars fillers have undergone continuous improvements over the past two decades without neglecting the proven components. The focus has always been to bring an inexpensive but very flexible machine onto the market that is modular and compact at the same time. We use both servo technology and mechanical components, whereby pneumatic parts are largely avoided due to the noise pollution and the associated high energy consumption. The machine is quiet. How quietly you can hear from the Audio file. And as usual, the engine room is made of stainless steel and welded, product-carrying parts are from AISI 316L.

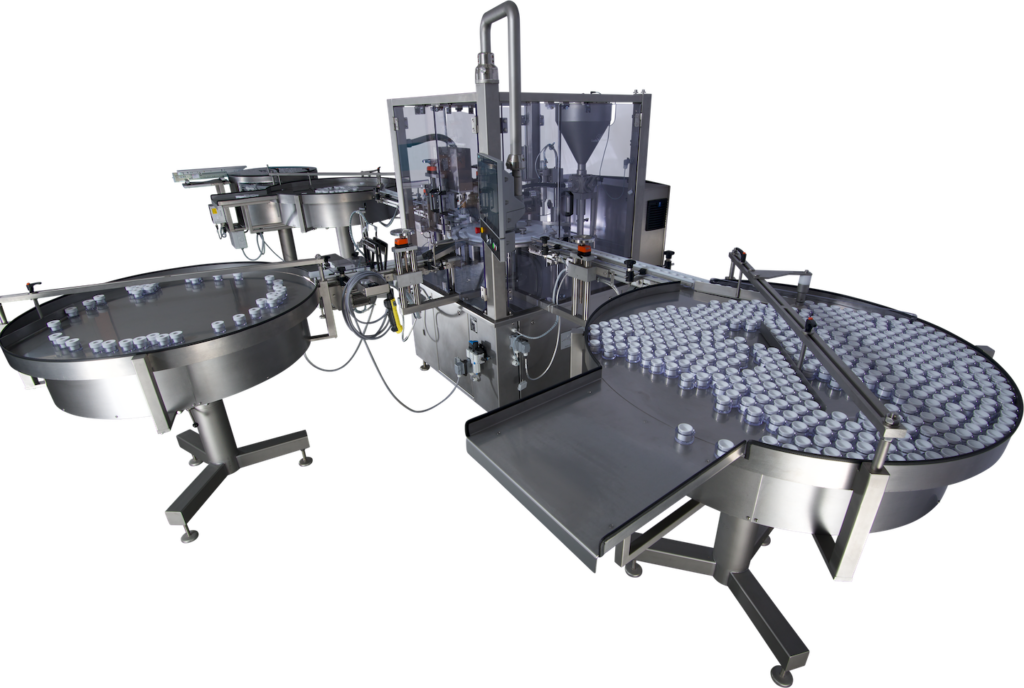

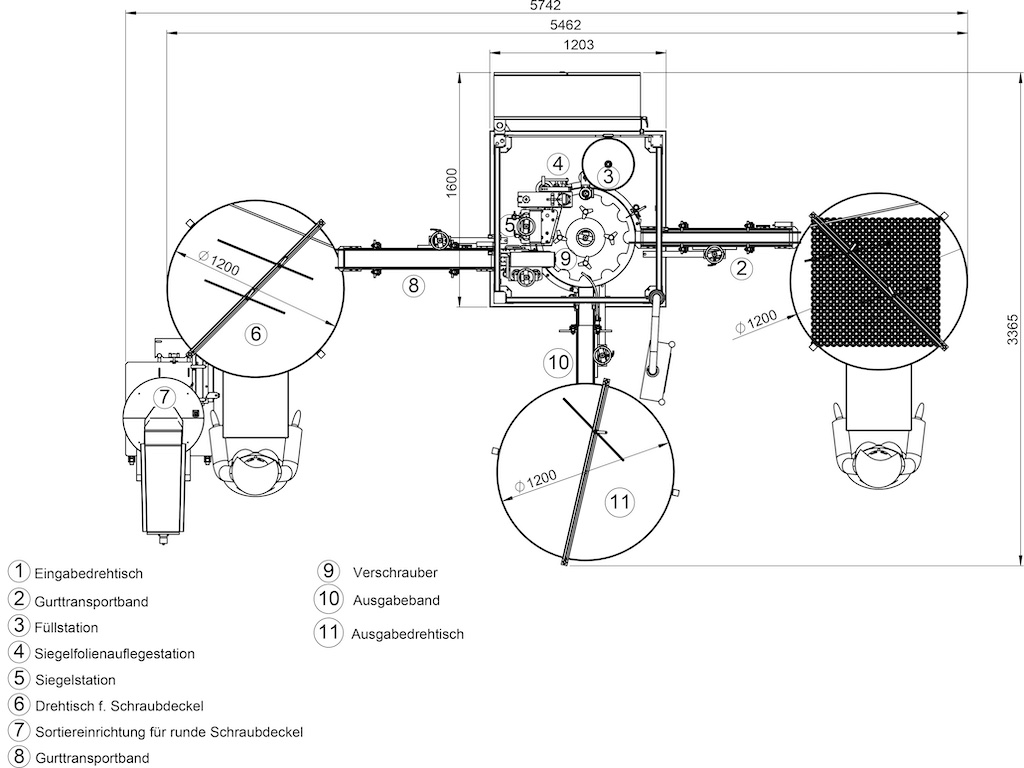

This year we have delivered out new AL31Ti to Pretty Nail Shop . Jars are processed in round, but also in square shape, the filling volumes are between 5 and 50ml. But of course, our machine can also handle large jars up to 300ml, in special designs even up to 500ml. The challenge was to fill the smallest quantities, i.e. as little product residue as possible should remain in the machine after production. These are mainly high-viscosity UV gels, a product that certainly places high demands on the filling technology. The layout shows how compact the system was actually built.

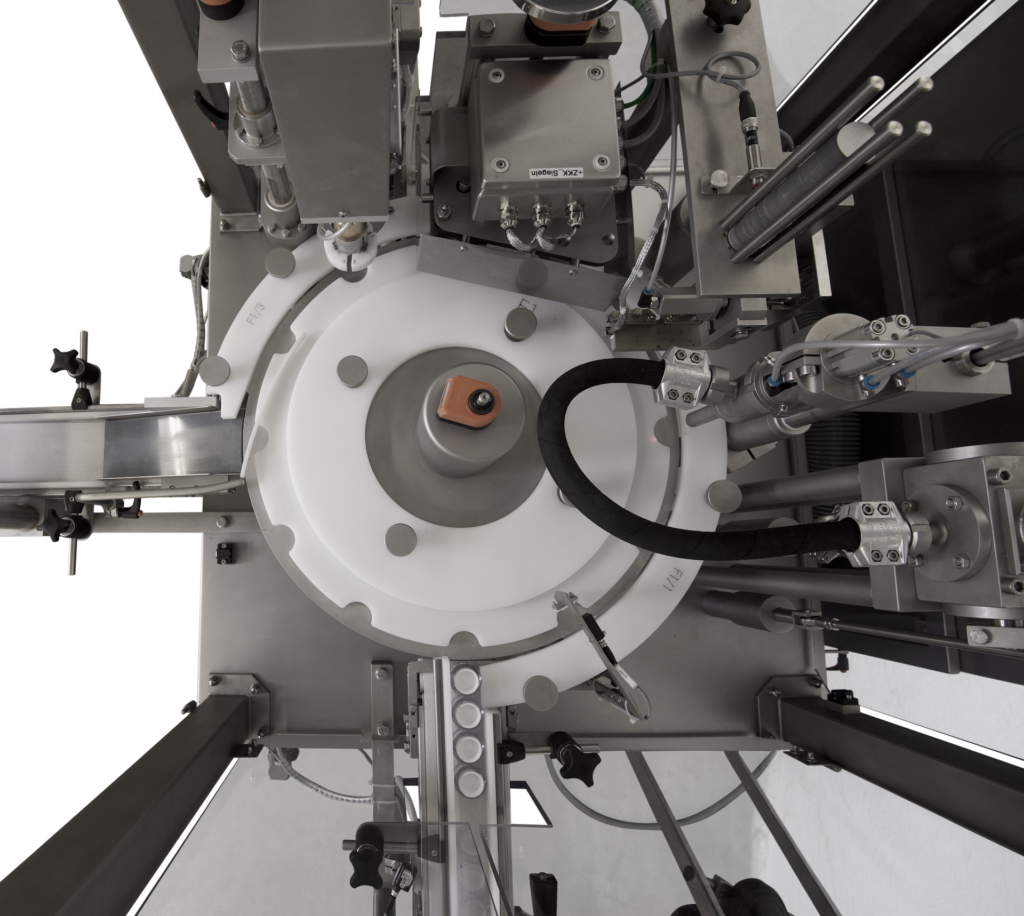

The functions consist of transporting the lids, optionally via a turntable or sorting bowl, feeding in the containers using a turntable, filling, sealing, screwing and discharging the finished jars onto the turntable. Of course, the individual steps include all the necessary control stations.

The sequence of the work stations is cam-controlled. Exceptions are the servo drives of the filling station and pneumatically driven auxiliary functions such as the closing valve in the filling nozzle. Sealing foils are provided in a storage chute. However, we also offer the option of punching a sealing film. The AL31Ti single-lane rotary indexer is designed for 40 crucibles per minute.

A modern controller (SIEMENS) and a large display as an HMI with intuitive user guidance complete our system.

The machine has been in constant use since delivery and our customer is pleased with the flawless operation. For our part, we are delighted to have such a respected reference for our new AL31Ti. You can see a small “round trip” around the facility here .

0 Kommentare

Kommentar verfassen